Established in 1929, Morris Industries strives to provide the most innovative and up-to-date products in the agricultural seeding and tillage equipment market.

Morris' company history is grounded in innovation by understanding the needs of farmers. Its team of research and development specialists continually develops new and more efficient equipment such as the 9 Series Air Cart and C2 Contour Drill to assist customers with better farming processes.

Backed with quality products and support, Morris has expanded out of North America to be one of the leading international brands, providing innovative equipment to Australia, Kazakhstan, Germany, Ukraine, France, England, New Zealand, South Africa and Russia.

As testament to its commitment to continually improving products and services for exceptional customer requirements and customer satisfaction, Morris is ISO 9001:2008 certified.

In 2002, Morris expanded its line of hay hauling and stacking equipment by acquiring ProAG Designs, Inc., a Montana-based manufacturer of large bale hauling and stacking machines.

As Australian distributor for Morris seeding and tillage equipment, McIntosh Distribution works closely with Morris and Australian farmers to provide solutions for better and more efficient farming processes.

“Morris is a seeding and tillage market leader with air carts, air drills and seeders to make your farming processes more productive and efficient”

Morris’ revolutionary new Quantum air drill takes your operation to the next level with increased seeding efficiency, yield potential, and equipment longevity. More than just a new model, Quantum is a giant leap forward in agricultural innovation — and one of the biggest achievements in Morris' 90-year history.

Download Brochure Find a DealerEXACT DEPTH CONTROL

With a 16-inch range of travel, Quantum’s opener is much less prone to carve into the crowns of hills or lose seed placement in shallow depressions.

SUPERIOR SEED-SOIL CONTACT

A well-established field is the most important step toward maximum yield potential. Quantum’s improved row unit design provides ideal soil-seed contact for rapid uniform crop emergence.

OUTSTANDING PRODUCT SEPARATION

Morris has measured the impact of fertilizer rates with double-shoot openers on a variety of soils and conditions. Quantum’s double-shoot openers reinforce the outstanding results.

Quantum’s advanced frame is connected with chrome pins that are 27% larger than the previous design - resulting in a stronger joint with greater durability.

HEAVY-DUTY HITCH UPGRADE

The new heavy-duty hitch uses a greaseable, articulating hitch clevis for excellent wear life.

LARGE TYRES, ALL- AROUND

Quantum’s tyre design keeps you rolling with flexible durability for the long haul.

IMPROVED ROW UNIT

The improved row unit provides outstanding row-to-row depth precision and a more durable design that minimizes steel-on-steel wear.

Quantum provides a wide range of imperial and metric row unit spacing at the exact working width of the drill.

DEEPER DEPTH RANGE

The air drill’s opener cam uses the same proven system as the C2 Contour.

THE INDUSTRY'S TOP TYRE FLOATATION

Quantum’s larger diameter tyres let you float through wet spots with ease.

Smooth internal surfaces make the new design less prone to plugging, while also preventing fertilizer and seed dust build-up

ACTIVE OPENER HYDRAULIC CONTROL

Quantum has an active hydraulic system to control opener pressure, a reducing system to minimize hydraulic flow, and a number of other user-friendly options.

FULLY CONTROLLED TRAFFIC FARMING

Spacing is optimized for minimal tracks and soil compaction in controlled traffic fields.

Achieving a new level of performance, the Morris 9 Series Air Cart comes with a list of next generation innovations. Advancements include Input Control Technology (ICT), new tank configurations, left side auger and a redesigned stairway for easier access, a redesigned stairway and the Topcon X30 console.

Download Brochure Find a DealerAdvanced Style

The Morris 9 Series tank shape is designed to increase filling efficiencies and operator safety. Silver metallic paint and clear coat provides outstanding toughness and resistance.

New Tank Design

Filling of the tanks has been made easier with the symmetrical tank design. The tank lids are closer together and with the optional hydraulic assist the operator can use the wireless controller to adjust the positioning of the spout on the auger/conveyor.

New Tank Lid Design

The lid design incorporates a gas cylinder to assist the operator when opening and closing the tanks. The new handle is also positioned so that the operator does not need to stand above the lids to open them. The lids can then rotate to sit along the tank panel and reduce clutter on the walkway.

New Stairway

The stairway has been relocated to the rear of the air cart and can be accessed from the auger side. A retractable section provides a low step height when in use then slides up and locks it out of the way. The sliding section has 2 larger gas cylinders that help lift and hold the stairs until locked in position.

Left Side Access

The auger/conveyor have been moved to the left side for easier access when filling. A new 6-function wireless remote has been included with the optional hydraulic assist to reduce operator fatigue.

New Walkway

The walkway is positioned to allow an operator more room to work and avoid dust when filling the tanks. Handrails around the walkway platform offer excellent protection for a more secure and safe work area.

Precision

The 9 Series is engineered to offer the most precise air delivery system to control input costs.

Flat Fan Divider Heads

This patented design maintains a smooth horizontal flow of products as it leaves the primary runs to the divide into each secondary run. This precise and efficient system ensures that germination, growth and vigour are protected.

Meter Bodies

The meter bodies have been updated to include single person operation of the inspection and calibration access doors. The operator can quickly inspect the seed-plate in each meter body. New calibration doors speed up calibration time because the operator does not have to pick up parts from the ground.

High Efficient Fan

An industrial piston-type hydraulic motor powers the 43cm (17”) diameter forward curved fan. Large hydraulic lines decrease flow restriction for less heat build up under higher fan speeds. A dual fan option is available for large width seeding tools.

Metering Wheels

The time-proven spiral fluted metering wheel is the centre of the metering system. The spiral flute provides a continuous flow of product into the air stream. The meter body on the 9800 air cart model has been widened to accommodate up to 10 metering wheels to utilise larger seeding units.

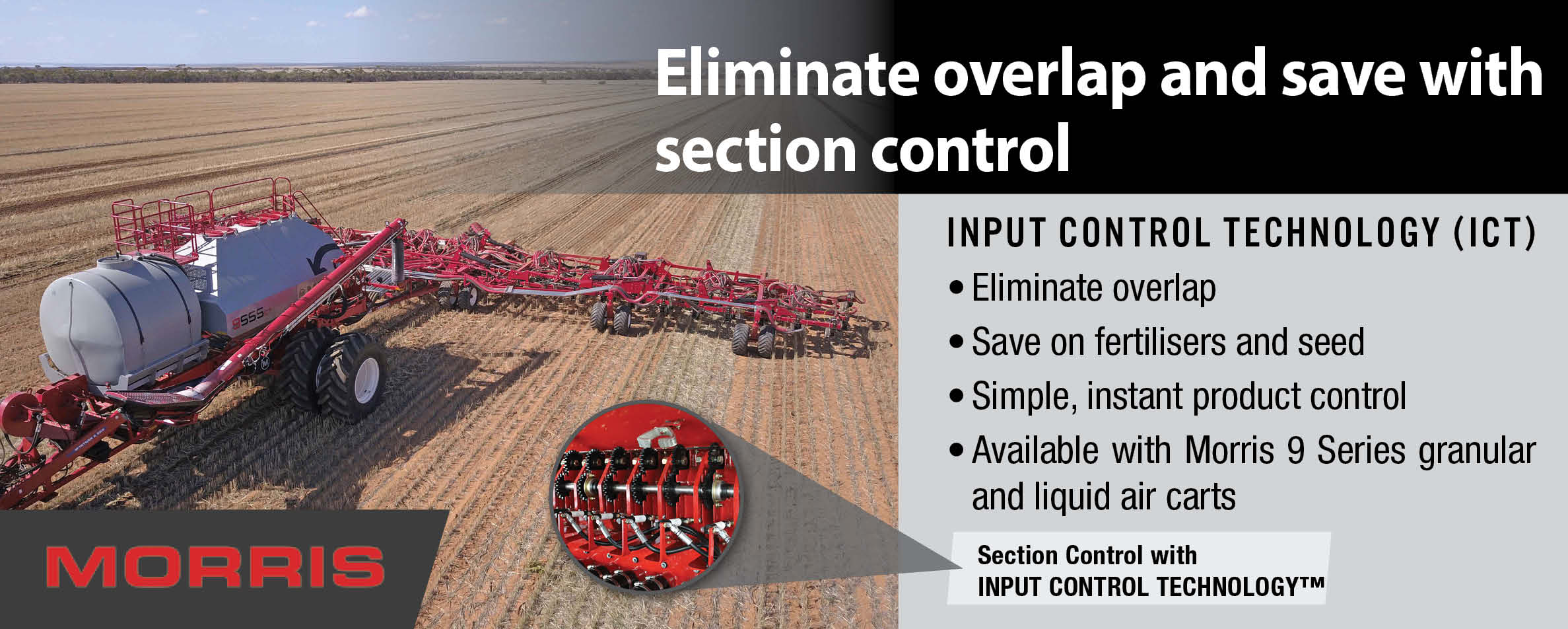

Input Control Technology

Advanced engineering provides a more cost-effective and reliable way to conserve crop inputs. The Morris Input Control Technology™ is engineered to prevent overlaps by stopping product flow over the sections that are not required. The ICT system uses a unique drive system to engage or disengage the individual metering wheels, which stops the product in each tank from flowing instantly.

Instant Overlap Control

With the simple sprocket-driven system, the metering wheel is either engaged and turning or is stopped. The metering wheels for each section are always full seed and fertiliser, which reduces the time required to charge the system when beginning the next pass. This sprocket-driven system is visible to the operator when inspecting the tanks.

Rate Control

The 9 Series can be fitted with most rate controllers including established brands such as Top Con, Trimble, CNH, and John Deere. By integrating these systems to your Morris air cart, the installation of these systems allows you total flexibility at your fingertips, including variable rate application (VRA) and liquid control.

Metering Options

Equip your 9 Series with either variable rate or mechanical drive metering.

Mechanical Drive Metering

Quick-change sprockets provide simple, reliable adjustments between crops and posi-drive transmission uses a positive lock on all drive sprockets to deliver smooth and reliable metering.

Seed and fertiliser rate charts have been added to the tanks to allow for a quick reference when starting calibrations of different products.

Fan speed, shaft rotation, bin levels, acres seeded and other critical data are available with the standard monitor system.

Variable Rate Metering

The Morris variable rate options is quick and responsive for precise ‘on the go’ rate changes. The VRT option features Top Con’s industry-leading X30 Console with an intuitive multiview interface.

Other consoles utilising CANBUS and ISOBUS can also be used for variable rate functions.

Tank Sizes

The 9 Series are available in a number of capacities and models.

|

Model |

Bin Sizes (Bushels) |

Bin Sizes (L) |

Total Litres |

TBH Trike |

TBH Quad |

TBT |

Liquid (L) |

Frame Size |

|

9365 |

182 182 |

6,414 6,414 |

12,828 |

Std |

Opt |

Y |

5,000 |

Regular |

|

9450 |

182 182 86 |

6,414 6,414 3,030 |

15,858 |

Std |

Opt |

Y |

3,000 |

Regular |

|

9535 |

182 182 86 86 |

6,414 6,414 3,030 3,030 |

18,888 |

N/A |

Std |

Y |

Liquid ready |

Regular |

|

9445 |

221 221 |

7,788 7,788 |

15,576 |

N/A |

Std |

Y |

5,000 7,000 |

Large |

|

9550 |

221 221 107 |

7,788 7,788 3,772 |

19,348 |

N/A |

Std |

Y |

5,000 |

Large |

|

9650 |

221 221 107 107 |

7,788 7,788 3,772 3,772 |

23,120 |

N/A |

Std |

Y |

Liquid ready |

Large |

|

9555 |

265 284 |

9,339 10,008 |

19,347 |

N/A |

Std |

Y |

7,000 |

XLarge |

|

9680 |

284 265 133 |

10,008 9,339 4,700 |

24,047 |

N/A |

Std |

Y |

5,000 |

XLarge |

|

9800 |

284 265 133 133 |

10,008 9,339 4,700 4,700 |

28,747 |

N/A |

Std |

Y |

Liquid ready |

XLarge |

|

9652 |

182 182 Liquid 1 Liquid 2 |

6,414 6,414 5,000 5,000 |

22,828 |

N/A |

N/A |

Y |

(x2) 5,000 |

XLarge |

|

9682 |

331 349 |

11,664 12,298 |

23,962 |

N/A |

Std |

Y |

7,000 |

XXLarge |

|

9843 |

349 331 162 |

12,298 11,664 5,709 |

29,671 |

N/A |

Std |

Y |

Liquid ready |

XXLarge |

|

91000 |

349 331 162 162 |

12,298 11,664 5,709 5,709 |

35,380 |

N/A |

Std |

N/A |

Liquid ready |

XXLarge |

We also have on-board liquid options available for most Morris 9 Series models. Speak to your dealer today to see what best suits your farming practices.

Loaded with Australian customer-inspired ideas and technology, the Morris 10-series aims to minimise the time spent on seeding and filling operations and to maximise the number of hectares planted for each tank fill.

*DESIGNED TO COMPLEMENT THE 9 SERIES RANGE*

MODELS AVAILABLE:

Seed with Confidence.

Less Time Filling. More Time Seeding.

Variable Rate by Section.

Made for Australian Conditions.

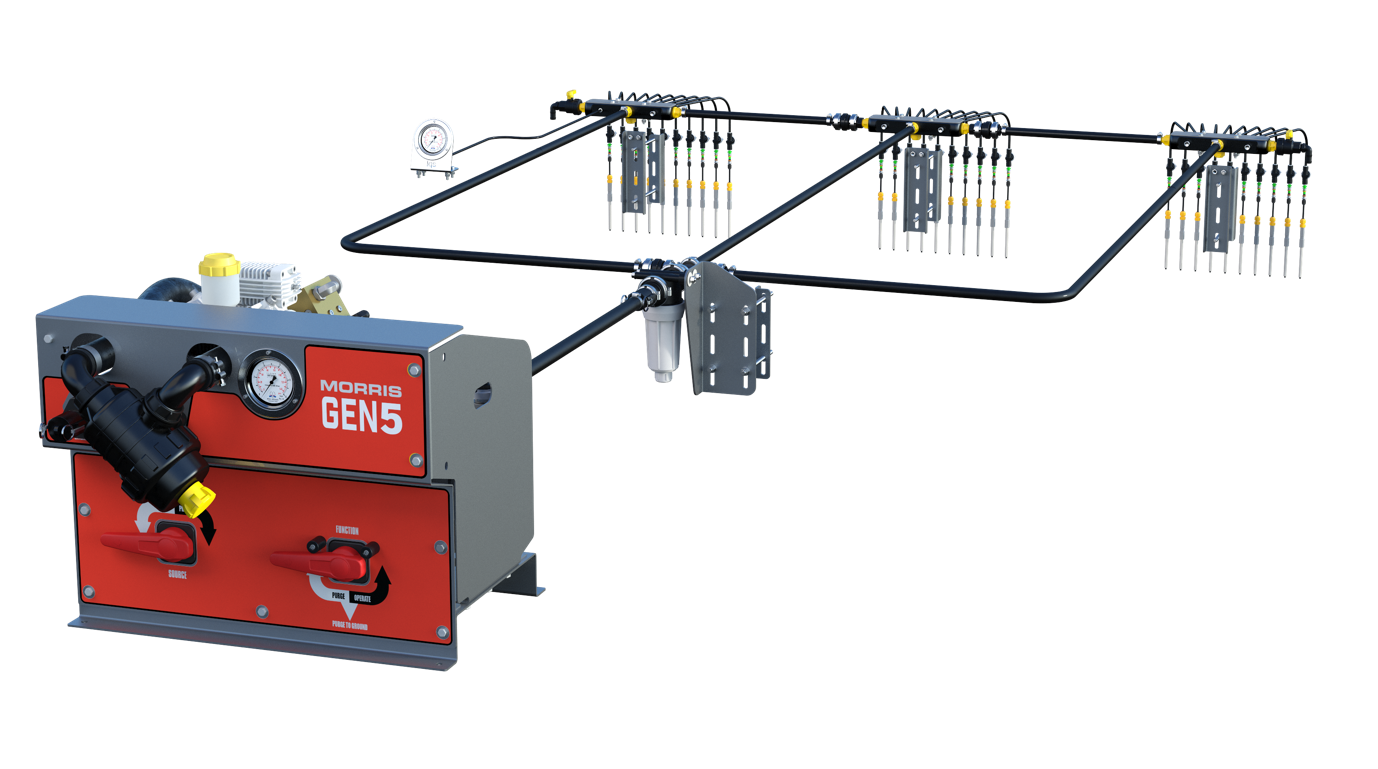

Since 2004 Liquid Systems (SA) has been supplying reliable and precise liquid delivery systems to McIntosh Distribution. The company’s systems are used around the world for accurate in-furrow injection of liquid nutrients.

Liquid Systems' new GEN5 Modules are super compact and have been designed for precise, even and accurate in-furrow application of single/dual liquid with straight forward operation. Simple flexibility to go section control and/or dual liquid. The systems are more efficient, faster, reliable, better supported for the farmers of the future.

The GEN5 Modules will provide farmers with flexibility and accurate rate control over nutrient application.

Download Brochure Find a Dealer

GEN5 MODULE

The MORRIS GEN5 is a single liquid auto-rate pump and control module. Upgrade easily to a Dual system or add Section Control at any time.

GEN5 180 MODULE

The MORRIS GEN5 180 is a single liquid auto-rate pump and control module. Upgrade easily to a Dual system or add Section Control at any time.

It offers a powerful 170 L/min (45 Ga/min) This provides capacity for applying liquids at higher rates with good tank agitation for larger tanks (5000L and over).

It offers a powerful 126 L/min (33 Ga/min). This provides capacity for applying liquids at higher rates with good tank agitation for up to 5000L tank capacity.

All systems can be integrated with many precision ag systems such as Ag Leader®, John Deere, Topcon, Raven, Trimble or any ISOBUS compatible display. This allows for accurate documentation of nutrient application and map/GPS based variable rate control.GEN5 can be used for subsurface in-furrow application or pressurized surface banding of liquid nutrients and crop care products.

Built-in fail-safe mechanisms help protect the system and personnel from operator errors and externally induced faults.

Each module is factory Wet-Tested before being shipped.

The system is installed with confidence, backed up with full support and service from McIntosh Distribution.

Features include accurate metering and distribution, single- or double-shoot options and tow-behind or tow-between configurations. The 9s air carts are available in three model sizes from 240-bushel to 300-bushel tank capacities. Silver metallic paint and clear coat provides outstanding toughness and resistance.

High Flow Fan

A high-flow fan gives added product-carrying capacity. The fan’s piston hydraulic motor is 98% efficient and rated for 10,000 hours of service.

Variable Rate System

The optional variable rate system with in-cab control features the Topcon X30. It allows you to change rates on the go with the press of a button.

Mechanical Ground Drive

Uses a positive lock on all drive sprockets to deliver smooth and reliable metering. The positive ground drive from the wheel compensates for any changes in ground speed, ensuring precise product rates at all times.

Monitoring

An easy-to-read monitor provides accurate data for ground speed, fan speed, bin level, field-acres seeded, total acres seeded, and more. Equipped with Vansco monitor for mechanical drive and Topcon console for variable rate.

Auger

The 9s Series auger is double-hinged for exceptional balance and is available with a standard 8-inch auger or an optional 10-inch auger. Choose either standard flighting or brush flighting for gentle handling of pulse crops.

Walk-Through Design

A unique walk-through design with a non-slip surface gives safe and easy access to loading areas. When the auger is down, access to the platform is available from both sides of the tank.

Diverter Valve

The diverter valve makes it easy to switch between single and double shoot. The valve allows the product in each tank to combine evenly into one air stream. Or you can choose to keep the product separate.

Metering System

Unique, spiral-fluted metering wheels gently roll product into the air stream in a constant flow. Metering wheels are matched with divider heads to ensure accuracy and efficiency when seeding a full range of seed varieties. Stainless steel collectors provide years of usage with out corrosion. Regular meter body or coated meter body option for high corrosive or sticky materials.

Easy Access

The 9s air carts include a quick release access meter body door and quick release collector door offer easy access to meter wheels and rate calibration.

Adjustable Plenum

When double shooting, a fully adjustable plenum lets you divert more air to the meter with heavier products and higher rates of application, and less with lighter or more fragile products.

Air Delivery

A unique Morris design delivers a smooth, horizontal flow of material that eliminates abrupt directional changes and reduces seed damage. The patented flat fan divider head distributes product evenly to each seed boot for uniform emergence.

Sizes and Configurations

Air carts are available in 240-bushel (two-tank), 252-bushel (three-tank) or 300-bushel (two-tank) capacities, in either tow-behind or tow-between models.

Third Tank

A third-tank configuration allows broadcasting option for small oil seeds and grasses, starter fertilizer, or granular herbicide. The third tank option is available for 9240 and 9300 models.

Controlled Traffic

Controlled traffic farming is the practice of repeatedly driving in the same wheel tracks with all of your equipment. This makes for more efficient use of farmland and increased overall fuel savings, as it is easier to pull equipment on compacted soil. The Controlled Traffic tow-behind air cart can be configured to 3-meter track widths.

The market leading trash flow characteristics of the C3 Contour and the Quantum have been adapted from the C2 Contour, the best trash flow design in the industry.

The C2 Contour was renowned for its simple operation, superior trash flow and agronomic success. The Quantum release demonstrated superior digging ability and continued depth control and accuracy. Morris developed the C3 Contour for large scale producers who prefer an 80 or 90ft bar option, combining the simplicity, performance & reliability of the Morris C2 and Quantum bars.

Key Features

Increased Depth Range

The notched cam-and-pin system adjusts depth at 6mm intervals. Rotate the cam by hand and insert the pin to lock in the desired seeding depth.

Floatation Lug Tyres

Standard on all C3 bars, the flattened ‘V’ pattern on the lug tyre minimises compaction and sealing in susceptible soils whilst providing superior floatation.

Upgraded Row Unit Features

The shank holder has been extended to improve the trip action for faster release off rocks. The linkage pivots are all 1” chrome pins inside hardened plastic bushings that eliminate steel on steel wear and negate the need for greasing.

Upright Air Kits

Standard on all C3 bars, the Australian designed and manufactured upright Air Kit is available for owners who prefer this style of air distribution.

Active Opener Hydraulics

The C3 Contour uses the same proven active hydraulic system developed for the Quantum to control opener pressure. It features a reducing system to minimise hydraulic flow requirements during operation.

Auto Pack

To meet varying pressure requirements and achieve ideal packing, Auto-Pack allows the operator to set the desired packing pressure on the press wheel. Auto-Pack will then maintain that desired pressure constantly by varying the hydraulic pressure on the opener assembly as conditions change across the paddock.

Liquid Option

A full liquid kit including manifolds, friction tubing/line meter, mounting brackets and delivery to the boot can be supplied. All final delivery liquid hoses contain a non-drip valve to prevent liquid fertiliser leaking into the frame during folding.

Packer Wheel Options

Opener Options

The combination CX 8105 seeding system offers the precision of the Contour precision drill with the seed metering and air cart technology from Morris.

Narrow Transport

The 9.84 feet (3 m) transport width makes moving from field-to-field safe and easy.

Articulated Design

The articulated design reduces weight transfer and increases land-following ability. The pivot allows the cart to move independently from the drill, side to side and front to back which improves stability and seeding accuracy in all field conditions.

Working Widths

The CX 8105 is available in 25 feet (7.62 m) or 31 feet (9.45 m) working widths with the choice of 10 inch (25.4 cm) or 12 inch (30.5 cm) row spacing.

Air Cart Tank Access

The folding ladder and catwalk provides easy access to the air cart tanks.

Independent Opener Technology

The independent opener features parallel linkage for ultra-precise seed and fertilizer placement. Each opener follows the contour of the ground, even on hills. Adjustable on-row packer wheels pressure provides excellent seed to soil contact.

Shank Design

At the heart of the C2 Contour’s ability to shed residue is the design of the single shank. The reclined 12-degree angle moves residue up and off the shank faster. The distance from the ground level to the catch point is 21 inches (53 cm) to greatly reduce the potential for crop residue to bunch.

Parallel Linkage

The true-one-to one parallel linkage maintains a constant opener angle relative to the soil and opener depth relative to the packer wheel through its range of travel. The opener can contour up 10 inches (25 cm) and down 7 inches (18 cm).

Depth Setting

The opener cam is up and away from the ground, so opener adjustments are much easier to make. Fine-tune your seeding depth without tools or heavy lifting. Rotate the cam by hand and insert the pin to lock in the desired seeding depth.

Hydraulic Accumulator

Pressure is maintained on the opener cylinders through a passive hydraulic accumulator system, which acts as a hydraulic cushion for the trips and reduces the demand on the tractor hydraulics. Pressure can be monitored from the tractor cab.

Capacity

The 105-bushel (3695-liter) capacity features 60/40 split tanks and an optional 10-bushel (352-liter) third tank.

Precise Metering System

The patented metering system allows quick and easy change over from single- to double -shoot. The spiral fluted metering wheel gently rolls a consistent flow of product into the air stream. This unique design eliminates the need to change wheels and reduces the chance of seed damage and uneven metering.

Convenience

All in one seed plates save time. One quick change lets you meter fine, medium or coarse product. Slide shutoffs on all tanks provide access to the meter components without having to empty product from the tanks. A hydraulic valve manifold providing all operator adjustments is conveniently located on the air cart.

9930 Mid Western Hwy

Cowra NSW, 2794

Phone: (02) 6341 3270

Website: View

Email: Contact Dealer

100-106 Forbes Rd

Parkes NSW, 2870

Phone: (02) 6862 3888

Website: View

Email: Contact Dealer

53 Richardson Rd

Dubbo NSW, 2830

Phone: (02) 6884 2767

Website: View

Email: Contact Dealer

226 Neeld St

West Wyalong NSW, 2671

Phone: (02) 6972 1057

Website: View

77-79 Commercial Street

Walla Walla NSW, 2659

Phone: (02) 6029 2151

Website: View

Email: Contact Dealer

51-53 Balo St

Moree NSW, 2400

Phone: (02) 6752 2044

Website: View

Email: Contact Dealer

53 Francis St

Narrabri NSW, 2390

Phone: (02) 6792 1988

Website: View

Email: Contact Dealer

2 Parkes Rd

Forbes NSW, 2871

Phone: (02) 6852 3211

Website: View

Email: Contact Dealer

140 Mackay Avenue

Yoogali (Griffith) NSW, 2680

Phone: (02) 6964 5959

Website: View

Email: Contact Dealer

42-44 Mullaley Road

Gunnedah NSW, 2380

Phone: (02) 6742 5777

Website: View

Email: Contact Dealer

46 Dampier Street

Tamworth NSW, 2380

Phone: (02) 6765 5244

Website: View

Email: Contact Dealer

17563 Warrego Highway

Dalby QLD, 4405

Phone: (07) 4662 2288

Website: View

Email: Contact Dealer

Stephens Street

Booleroo Centre SA, 5482

Phone: (08) 8667 2002

Website: View

Email: Contact Dealer

Goldsworthy St

Kadina SA, 5554

Phone: (08) 8821 1188

Website: View

Email: Contact Dealer

23 Henderson Ave

Cleve SA, 5640

Phone: (08) 8628 2100

Website: View

Email: Contact Dealer

11 Secker Ct

Cummins SA, 5631

Phone: (08) 8676 2103

Website: View

Email: Contact Dealer

1-2 Miller Crescent

Kimba SA, 5641

Phone: (08) 8627 2371

Website: View

Email: Contact Dealer

21 Fuschia Rd

Murray Bridge SA, 5253

Phone: (08) 8531 2244

Website: View

Email: Contact Dealer

3 Camacs Rd

Riverton SA, 5412

Phone: (08) 8847 2804

Website: View

Email: Contact Dealer

Eyre Highway

Wudinna SA, 5652

Phone: (08) 8680 2200

Website: View

Email: Contact Dealer

1917 Bookpumong Rd

Loxton SA, 5333

Phone: (08) 8584 5575

Website: View

Email: Contact Dealer

40 Railway Terrace S

Pinnaroo SA, 5304

Phone: (08) 8577 8129

Website: View

Email: Contact Dealer

72 Princes Hwy

Meningie SA, 5264

Phone: (08) 8575 1588

Website: View

Email: Contact Dealer

35 Dukes Hwy

Bordertown SA, 5268

Phone: (08) 8752 0633

Website: View

Email: Contact Dealer

38 Mines Road

Kadina SA, 5554

Phone: (08) 8821 1999

Website: View

33 Elizabeth Street

Maitland SA, 5572

Phone: (08) 8832 2801

Website: View

8 Sales Yard Road

Swan Hill VIC, 3585

Phone: (03) 5032 1578

Website: View

Email: Contact Dealer

236 Henty Hwy

Warracknabeal VIC, 3393

Phone: (03) 5394 1070

Website: View

Email: Contact Dealer

92 Karook St

Cobram VIC, 3644

Phone: (03) 5871 3333

Website: View

Email: Contact Dealer

37- 41 Cornelia Creek Rd

Echuca VIC, 3564

Phone: (03) 5482 2788

Website: View

Email: Contact Dealer

49 Ferrars St

Rokewood VIC, 3330

Phone: (03) 5346 1223

Website: View

Email: Contact Dealer

16 Osburn Street

Wodonga VIC, 3690

Phone: (02) 60246444

Website: View

Email: Contact Dealer

5 Wiltshire Lane

Ballarat VIC, 3356

Phone: (03) 5332 0566

Website: View

Email: Contact Dealer

64 Norseman Road

Esperance WA, 6450

Phone: (08) 9071 1155

Website: View

Email: Contact Dealer

Unit 2/191 Chester Pass Rd

Albany WA, 6330

Phone: (08) 9847 4255

Website: View

Email: Contact Dealer

160 Flores Road

Geraldton WA, 6531

Phone: (08) 9960 5500

Website: View

Email: Contact Dealer

Lot 4 Nyabing Road

Katanning WA, 6317

Phone: (08) 9821 7000

Website: View

Email: Contact Dealer

294 Pump Road

Kulin WA, 6365

Phone: (08) 9880 2556

Website: View

Email: Contact Dealer

52 Mitchell Street

Merredin WA, 6415

Phone: (08) 9041 1099

Website: View

Email: Contact Dealer

125 Gardiner Street

Moora WA, 6510

Phone: (08) 9651 1488

Website: View

Email: Contact Dealer

178 Wongan Road

Wongan Hills WA, 6603

Phone: (08) 9671 1300

Website: View

Email: Contact Dealer

8222 South West Highway

Waroona WA, 6215

Phone: (08) 9733 1462

Website: View

Email: Contact Dealer

Lot 24 Stewart St

Narrogin WA, 6312

Phone: (08) 9881 2222

Website: View

Email: Contact Dealer

1 Main Road

Cunderdin WA, 6407

Phone: (08) 9635 1003

Website: View

Email: Contact Dealer

23781 S Western Hwy

Hester Brook WA, 6255

Phone: (08) 9761 4500

Website: View

Email: Contact Dealer

64 Norseman Road

Esperance WA 6450

Phone: (08) 9071 1155

Fax: (08) 9071 3799

9930 Mid Western Hwy

Cowra NSW 2794

Phone: (02) 6341 3270

Fax:

100-106 Forbes Rd

Parkes NSW 2870

Phone: (02) 6862 3888

Fax:

53 Richardson Rd

Dubbo NSW 2830

Phone: (02) 6884 2767

Fax:

226 Neeld St

West Wyalong NSW 2671

Phone: (02) 6972 1057

Fax:

77-79 Commercial Street

Walla Walla NSW 2659

Phone: (02) 6029 2151

Fax:

53 Francis St

Narrabri NSW 2390

Phone: (02) 6792 1988

Fax:

17563 Warrego Highway

Dalby QLD 4405

Phone: (07) 4662 2288

Fax:

Stephens Street

Booleroo Centre SA 5482

Phone: (08) 8667 2002

Fax: (08) 8667 2008

23 Henderson Ave

Cleve SA 5640

Phone: (08) 8628 2100

Fax:

11 Secker Ct

Cummins SA 5631

Phone: (08) 8676 2103

Fax:

1-2 Miller Crescent

Kimba SA 5641

Phone: (08) 8627 2371

Fax:

21 Fuschia Rd

Murray Bridge SA 5253

Phone: (08) 8531 2244

Fax:

3 Camacs Rd

Riverton SA 5412

Phone: (08) 8847 2804

Fax:

Eyre Highway

Wudinna SA 5652

Phone: (08) 8680 2200

Fax:

1917 Bookpumong Rd

Loxton SA 5333

Phone: (08) 8584 5575

Fax:

40 Railway Terrace S

Pinnaroo SA 5304

Phone: (08) 8577 8129

Fax:

72 Princes Hwy

Meningie SA 5264

Phone: (08) 8575 1588

Fax:

35 Dukes Hwy

Bordertown SA 5268

Phone: (08) 8752 0633

Fax:

8 Sales Yard Road

Swan Hill VIC 3585

Phone: (03) 5032 1578

Fax:

236 Henty Hwy

Warracknabeal VIC 3393

Phone: (03) 5394 1070

Fax:

37- 41 Cornelia Creek Rd

Echuca VIC 3564

Phone: (03) 5482 2788

Fax:

49 Ferrars St

Rokewood VIC 3330

Phone: (03) 5346 1223

Fax: (03) 5346 1548

16 Osburn Street

Wodonga VIC 3690

Phone: (02) 60246444

Fax:

Unit 2/191 Chester Pass Rd

Albany WA 6330

Phone: (08) 9847 4255

Fax:

160 Flores Road

Geraldton WA 6531

Phone: (08) 9960 5500

Fax:

Lot 4 Nyabing Road

Katanning WA 6317

Phone: (08) 9821 7000

Fax:

294 Pump Road

Kulin WA 6365

Phone: (08) 9880 2556

Fax:

52 Mitchell Street

Merredin WA 6415

Phone: (08) 9041 1099

Fax: (08) 9041 1466

125 Gardiner Street

Moora WA 6510

Phone: (08) 9651 1488

Fax:

178 Wongan Road

Wongan Hills WA 6603

Phone: (08) 9671 1300

Fax:

8222 South West Highway

Waroona WA 6215

Phone: (08) 9733 1462

Fax:

2 Parkes Rd

Forbes NSW 2871

Phone: (02) 6852 3211

Fax:

Lot 24 Stewart St

Narrogin WA 6312

Phone: (08) 9881 2222

Fax:

1 Main Road

Cunderdin WA 6407

Phone: (08) 9635 1003

Fax:

5 Wiltshire Lane

Ballarat VIC 3356

Phone: (03) 5332 0566

Fax: (03) 5332 0575

33 Elizabeth Street

Maitland SA 5572

Phone: (08) 8832 2801

Fax:

23781 S Western Hwy

Hester Brook WA 6255

Phone: (08) 9761 4500

Fax:

140 Mackay Avenue

Yoogali (Griffith) NSW 2680

Phone: (02) 6964 5959

Fax:

42-44 Mullaley Road

Gunnedah NSW 2380

Phone: (02) 6742 5777

Fax:

46 Dampier Street

Tamworth NSW 2380

Phone: (02) 6765 5244

Fax: