16 November 2015

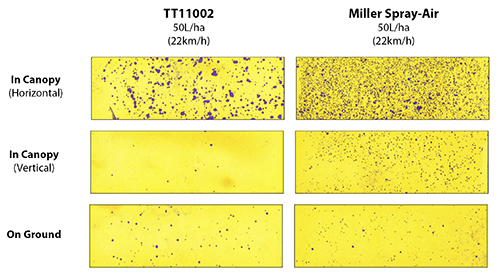

Pictured is the spray coverage and quality between standard TeeJet TT nozzles and the Miller Spray-Air system following testing in a dense oaten hay crop on Chris Hockey’s Gibson property.

The Miller Spray-Air technology at work, pushing the spray into the crop canopy.

SPRAYING comparisons using an air boom system against industry standard and another air-assisted unit near Esperance have shown improved spraying effectiveness with the latest technology.

With 20 years of use on the mechanical drive Miller Condor sprayer in North America and Canada, the Miller Spray-Air system is now available in Australia on the popular Miller Nitro, front-mounted self-propelled sprayer and local dealer, Staines Esperance, recently put it to the test.

In conjunction with national distributor, McIntosh Distribution, the system was directly compared with standard TeeJet Air Induction XR and TT nozzles, as well as an Airtec sprayer, in a 900-millimetre high, full canopy oaten hay crop on Chris Hockey’s Gibson property.

Travelling at a speed of 22 kilometres per hour, the systems sprayed water at a base rate of 50 litres/hr, with various air pressures used to target different droplet sizes. Tests with other speeds and rates were also performed.

The testing was conducted using water sensitive paper placed at three separate heights: on the ground, at a height of 500mm and vertically at 250mm inside the crop canopy.

Mike Symes, with McIntosh Distribution, said the significantly better spray coverage provided by the Miller Spray-Air system was immediately apparent.

He said the testing also showed surprising results at half the application rate (25L/hr) and speeds of 30km/hr.

“If you’re not effectively hitting the target, any weed that survives the chemical could develop resistance,’’ Mike said.

“The first thing you get with Spray-Air is a better spray job. You are getting more effective chemical use.’’

He said the spray quality achieved with Spray-Air was due to the simple mechanical principles the system employed to produce more consistent droplets, while carrying them at high velocity down to the target in a curtain of air.

Improved penetration, with better vertical coverage inside the canopy, can be expected whether spraying herbicides, fungicides or desiccating crops.

Further testing has shown similar results in stubbles and from early post-emergent spraying.

“The Miller Spray-Air has the potential to safely reduce application rates whilst maintaining the higher spraying speeds required in our farming systems,’’ Mike said.

“For growers, this means higher efficiency spraying with less filling and transport time and more time in the paddock, as well as application savings and improved timing of applications.’’

The Miller Spray-Air technology offers both managed droplet control and deep canopy penetration. It combines the benefits of both air-assist and air-atomisation into one powerful spray nozzle system. Growers have fingertip control of the droplet size, spray pattern and speed of the air blast spraying into their crops on the go.

The optimum-sized droplets (coarse, medium or very fine), which are created by patented Shear Guard PLUS Air Nozzles spaced every 25 centimetres (10 inches) along the air boom, are not affected by speed and pressure changes, ensuring uniform application.

The nozzles blast the droplets deep into crop canopies, ensuring complete top-to-bottom leaf surface coverage. The smaller controlled droplets and directed air blast allows efficient water and chemical usage.